Mantic Stages

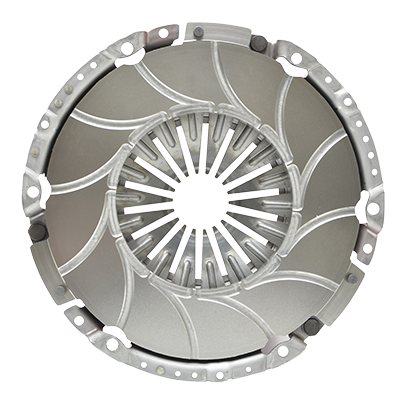

Mantic Stage 1 and Stage 2 clutch kit cover assemblies feature the patented ER2 Groove Design, which is a unique pattern CNC machined on the friction face of the pressure plate. This groove has been specifically designed to increase the Mean Effective Radius of the pressure place and assist in heat dissipation. The increase in the Mean Effective Radius of the cover assembly gives a significant increase in the torque capacity.

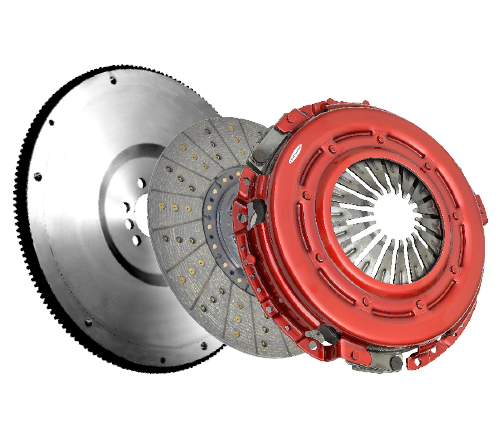

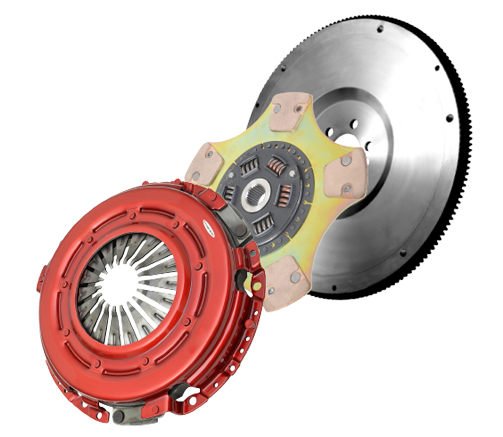

This clutch kit is specifically designed for the street performance market. The high torque capacity cover assembly’s pressure plate is manufactured from Spheroidal Graphite casting material, which has a yield strength 300% higher than standard castings. The materials microstructure also improves heat dispersion. In addition, the Mantic Stage 1 features our patented groove design, ER², CNC machined on the friction face of the pressure plate. Our stage 1 clutch system is capable of transmitting more torque than a standard clutch kit. This overall torque capacity increase has been achieved via higher clamp loads, increased Mean Effective Radius courtesy of the ER² designed pressure plate, improved heat displacement and use of a high coefficient of friction organic material on the clutch disc. The clutch disc features organic facing material of both sides of the clutch disc making the stage one clutch system the most driver friendly option in our range.

This clutch kit is specifically designed for the street performance market. The high torque capacity cover assembly’s pressure plate is manufactured from Spheroidal Graphite casting material, which has a yield strength 300% higher than standard castings. The materials microstructure also improves heat dispersion. In addition, the Mantic Stage 1 features our patented groove design, ER², CNC machined on the friction face of the pressure plate. Our stage 1 clutch system is capable of transmitting more torque than a standard clutch kit. This overall torque capacity increase has been achieved via higher clamp loads, increased Mean Effective Radius courtesy of the ER² designed pressure plate, improved heat displacement and use of a high coefficient of friction organic material on the clutch disc. The clutch disc features organic facing material of both sides of the clutch disc making the stage one clutch system the most driver friendly option in our range.

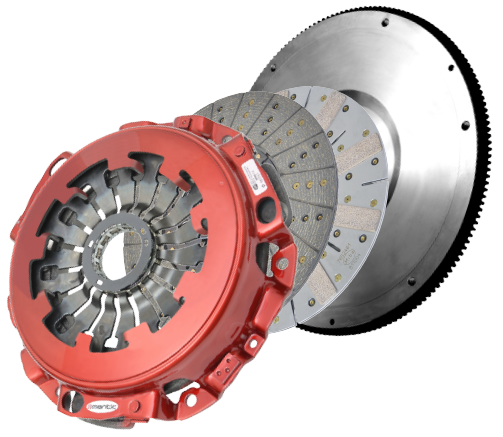

Designed for performance street / track day use where a higher torque capacity is required, but the vehicle may still be used for everyday driving. The stage 3 kit offers a high torque capacity cover assembly with an SG iron burst proof pressure plate, combined with a sprung centre and cushioned cerametallic clutch disc to provide high torque capacity for those looking for maximum street performance and occasional track use.

This clutch kit is specifically designed for the street performance market. The high torque capacity cover assembly’s pressure plate is manufactured from Spheroidal Graphite casting material, which has a yield strength 300% higher than standard castings. The materials microstructure also improves heat dispersion. In addition, the Mantic Stage 1 features our patented groove design, ER², CNC machined on the friction face of the pressure plate. Our stage 1 clutch system is capable of transmitting more torque than a standard clutch kit. This overall torque capacity increase has been achieved via higher clamp loads, increased Mean Effective Radius courtesy of the ER² designed pressure plate, improved heat displacement and use of a high coefficient of friction organic material on the clutch disc. The clutch disc features organic facing material of both sides of the clutch disc making the stage one clutch system the most driver friendly option in our range.

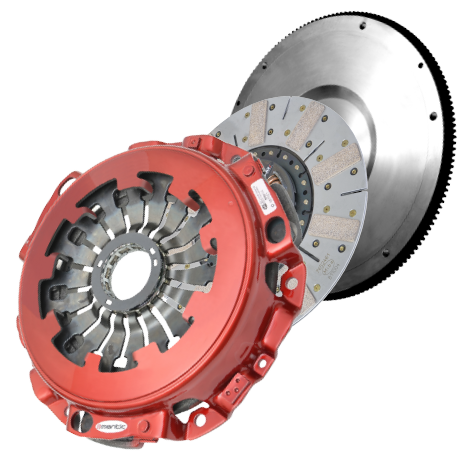

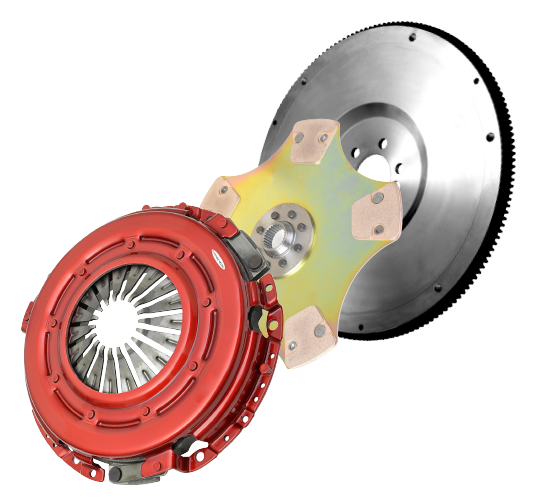

Our most aggressive system in the single disc range, the Stage 5 clutch is designed exclusively for track/motor sport applications. The stage 5 kit offers a high torque capacity cover assembly with an SG iron burst proof pressure plate, combined with a rigid hub, undampened Cerametallic Clutch Disc.