The flywheel’s role in a vehicle is to do the following;

- Provide a flat clamping surface for the clutch plate to match up to.

- Keep momentum; it’s a heavy mass that keep the crank turning

- Take heat way from the clutch disc/plate, acting as a heat sink

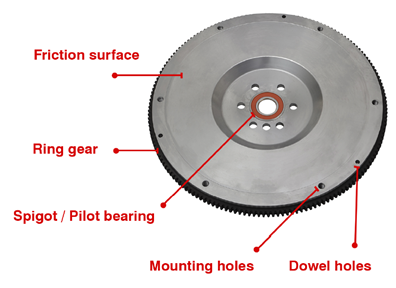

Because the flywheel is bolted directly to the crank, the flywheel will always spin at the same rate as the crank shaft of the engine. Around the outside of the flywheel you will find a ring gear. Although it is part of the flywheel, ring gears have nothing to do with the clutch itself. They work with the starter motor.