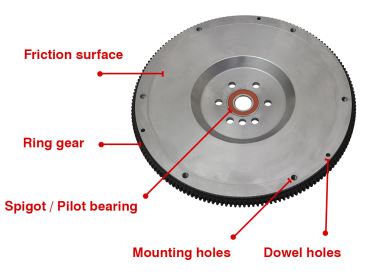

1. FLYWHEEL

The flywheel is one side of the vice. It is a big metal disc that bolts directly to the crankshaft. Its role is to:

- Provide a flat clamping surface for the clutch plate to match up to.

- Keep momentum, it’s heavy mass that keeps turning the crank.

- Take heat away from the clutch plate.

Because the flywheel is bolted directly to the crank, the flywheel will always spin at the same rate as the crank shaft of the engine. (Around the outside of the flywheel you will find a ring gear. Although it is part of the flywheel, ring gears have nothing to do with the clutch itself. They work with the starter motor)

2. GEARBOX INPUT SHAFT

A small but very strong shaft. At one end is a locating pin that sits in the centre of the flywheel/crank. A spigot bearing sits in the centre of the flywheel, on the locating pin of the shaft. Because the input shaft is not bolted to the crank, it does not turn with the crank, it just uses it as

a locating point. The opposite end of the shaft is connected to the gearbox. Along the shaft you’ll find gear teeth, called the spline, these match the centre hole of the clutch plate. The gearbox input shaft’s purpose is to:

- Line up the gearbox with the centre of the crank shaft, keeping the rest of the drive train staright and true to the crank.

- Give the clutch plate something to locate onto and position itself.