Dual Mass Flywheels were introduced to dampen driveline vibration and noise more effectively. The need for this escalated due to increased torque in modern engines (especially diesel engines) and consumers expectations of noise and vibration. (Valium)

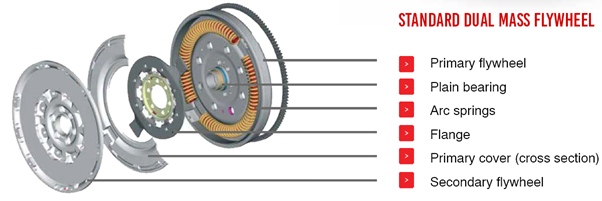

A Dual Mass Flywheel (DMF) is comprised of two flywheels that work together with dampening springs or planetary gears to reduce noise and vibrations.

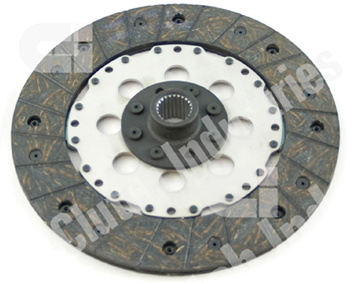

As the driveline dampening occurs in the flywheel most DMF clutch discs do not contain springs but are generally cushioned to give smooth engagement.

Although DMF’s are very effective at dampening driveline noise and vibration they have 4 major downfalls.

- Cost: the cost of a replacement DMF can be many times more than the cost of the clutch.

- Durability: due to the added complexity is it common that the DMF will fail before the clutch is fully worn.

- Unable to grind it is not generally recommended to grind a DMF meaning that in most cases the DMF must be replaced when the clutch is replaced.

- Poor heat sink: as a DMF is not a solid piece of steel it’s a poor heat sink to remove heat from the clutch disc.