Relates to: R287N, R377N, R388, R1144N, plus RPM kits

Background:

One of the most common calls received on the CI Technical Service Hotline concerns a rattle generated from the clutch fork/release bearing area on VN, VR and VS Commodore. The noise can be evident after a new clutch has been fitted. In most cases a second new clutch has been fitted, however the noise still persists.

CI’s investigations indicate that the actuation system is usually the source of the noise rather than the clutch kit installed. We recommend three areas to check in the clutch actuation system to prevent this noise. They are:

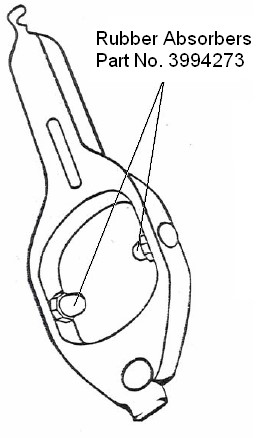

- The clutch fork should have two rubber absorbers fitted on the lugs that contact the release bearing. (The diagram on the Right indicates the intended location of the rubber absorbers).

In all cases we have seen, these rubber absorbers are missing, allowing the bearing to rattle on the fork. Fitting these absorbers will help to stop the bearing rattling. The genuine Holden part number for this part is 3994273.

- In other cases the clutch fork fouls on the bell housing, causing a rattle and possibly a rough feel in the clutch pedal.

- The release bearing guide on the front of the gearbox wears considerably allowing the bearing to rattle on this component. To stop the fork fouling it is necessary to remove sufficient material from the bell housing to stop the fork contacting. (https://skinnyninjamom.com/) Whenever a clutch is replaced inspect this area for wear. If any wear is evident the guide must be replaced.

Remember the clutch actuation system wears along with the clutch plate and cover assembly. Whenever a clutch is replaced the entire clutch system must be inspected and repaired as necessary to ensure the new clutch operates correctly.

Conclusion:

Contact CI: Clutch Industries is Australia’s only manufacturer with full Engineering and Test support services. Call us on 1300 369 787 if you require further technical support.